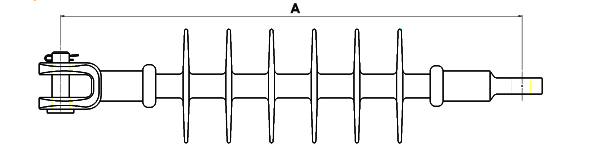

Polymer deadend insulator also named composite deadend insulator or silicone rubber deadend insulator. ANSI standard DS series distribution deadend insulators utilize a conventional silicone shed housing through injection molding and bonding to a fiberglass core.

Application:

Polymer deadend insulators are used on overhead lines operating upto 69 kV. These composite deadend insulators are used to support line conductors in suspension or deadend modes such as line terminations, angles, and tangents. Silicone rubber deadend insulators can be used with bare or covered conductors.

![]()

Housing and Sheds:

The housing and sheds of the polymer deadend insulator is one piece, high temperature vulcanized, injection molded silicone rubber that is chemically bonded to the fiber glass core rod. This ensures that the interface between the rubber and rod is impenetrable against moisture ingress.

Structure and features:

Orient polymer deadend Insulator Character:

| Items | Unit | Types | ||||

| DS-15 | DS-28 | DS-35 | DS-46 | DS-69 | ||

| Section length | mm | 330±15 | 430±15 | 525±60 | 590±50 | 750±75 |

| Min creepage distance | mm | 355 | 550 | 730 | 900 | 1190 |

| Low frequency dry flashover | kV | 90 | 130 | 145 | 180 | 220 |

| Low frequency wet flashover | kV | 65 | 100 | 130 | 145 | 185 |

| Positive critical impulse flashover | kV | 140 | 190 | 250 | 280 | 360 |

| Radio influence voltage | ||||||

| Test voltage | kV | 15 | 20 | 30 | 30 | 45 |

| Max. RIV @ 1000kHz | 10 | 10 | 10 | 10 | 10 | |

| Min SML | LB | 10000 | 10000 | 10000 | 10000 | 10000 |

| Min torsional load | FT-LB | 35 | 35 | 35 | 35 | 35 |