High Voltage Composite/Polymer Insulators: A Modern Solution for Transmission Lines

Composite insulators, also known as polymer insulators, have revolutionized high-voltage transmission systems. These units are essential for 110kV, 220kV, 330kV, and 500kV power lines, offering superior performance compared to traditional ceramic or glass types.

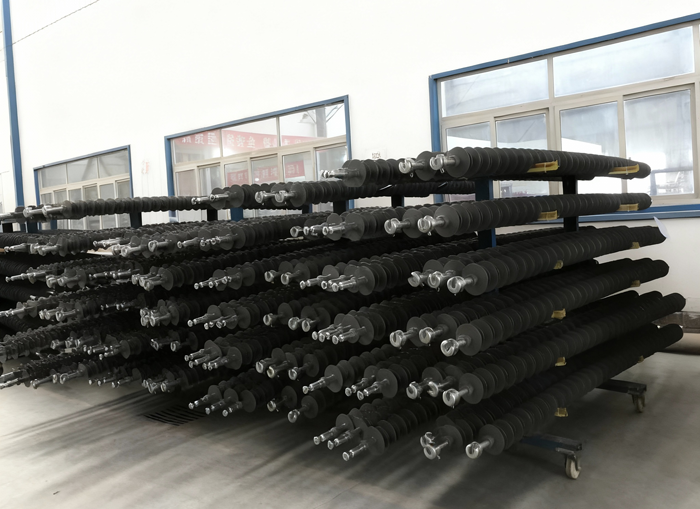

Composite suspension insulators are used primarily in straight-line spans to support conductor weight. Their lightweight polymer design, typically featuring a silicone rubber housing and a fiberglass core, provides excellent hydrophobicity, reducing leakage current and pollution flashover. This makes them ideal for polluted or coastal environments.

Composite tension insulators, employed at angle or dead-end structures, withstand mechanical tensile loads. Their robust construction ensures high strength-to-weight ratio and resistance to vandalism, corrosion, and UV degradation.

Key advantages include:

From 110kV to 500kV systems, composite/polymer insulators ensure reliable, long-lasting performance, supporting modern grid demands efficiently.

Some types composite suspension insulators and tension insulators are as follows:

| No. | Type |

Normal voltage (kV) |

SML (kN) |

Section lenght (mm) |

Creepage distance (mm) |

Arcing distance (mm) |

Power frequency wet withstand voltage (kV) |

Lightning impulse withstand voltage (kV) |

| 1 | FXBW-110/70 | 110 | 70 | 1240 | 3520 | 1220 | 230 | 550 |

| 2 | FXBW-110/120 | 120 | ||||||

| 3 | FXBW-110/160 | 160 | 1340 | 1180 | ||||

| 4 | FXBW-220/120 | 220 | 120 | 2240 | 7040 | 2220 | 395 | 1000 |

| 5 | FXBW-220/160 | 160 | 2200 | |||||

| 6 | FXBW-220/210 | 210 | ||||||

| 7 | FXBW-330/120 | 330 | 120 | 2390 | 10560 | 3050 | 570 | 1425 |

| 8 | FXBW-330/160 | 160 | ||||||

| 9 | FXBW-330/210 | 210 | ||||||

| 10 | FXBW-500/120 | 500 | 120 | 4050 | 16000 | 4600 | 740 | 2050 |

| 11 | FXBW-500/160 | 160 | ||||||

| 12 | FXBW500/210 | 210 | ||||||

| 13 | FXBW-500/300 | 300 | 4450 | 4500 | ||||

| 14 | FXBW-500/420 | 420 |